Currently, most glass processing manufacturers use the electric heating bending furnace to produce hot bent glass. This bending furnace is easy to control and operate and has no pollution to glass. The products manufactured by it have high quality and consistency.

Most have used the computer integrated control. Various parameters are set by the computer to achieve the programmatic control of the bending process.

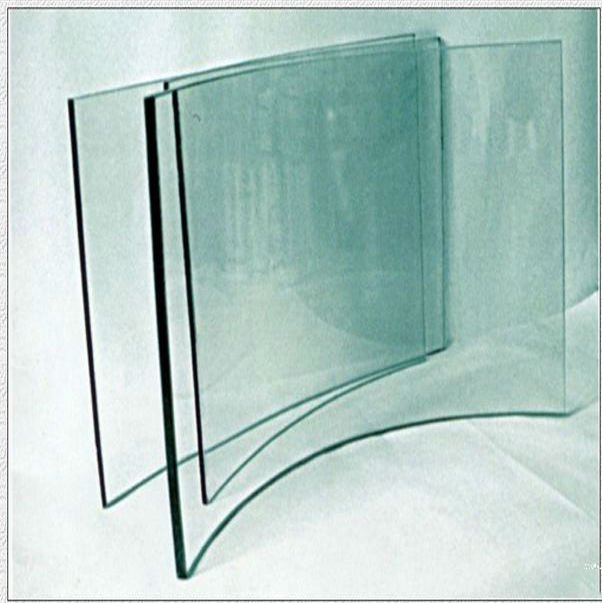

Two pieces of glass in big size and small size are selected. Silicon powder is uniformly sprinkled between the two pieces of glass. Then the glass is put on the

glass mould brick and heated. When the temperature reaches the softening point, the glass is softened until it has the same curvature with the glass mould brick under its own gravity or external pressure. Then stop heating and anneal slowly until the room temperature.

The following factors should be controlled during the bending process:

1) When preheating the glass, continuous heating or slow heating should be adopted to make a consistent temperature throughout the furnace;

2) The curvature of the two pieces of glass should be the same, or the laminated glass would have optical distortion;

3) The temperature of glass must reach the desired temperature of bending molding;

4) The glass mould brick is placed on the small car and kept horizontal;

5) When the furnace temperature reaches 640-710 ℃, the desired temperature of glass forming, glass will begin to deform under its own weight. In order to avoid the suddenly settling of glass at the temperature close to the softening temperature and avoid bending ripples on the glass surface, the operator must always observe the forming conditions and control the switch numbers, region and time of the heating lamps.

6) Glass should be annealed by slow cooling method and released when the temperature is below 100℃. During the bending process, the original stress has been eliminated. In order to prevent the new stress generated by the temperature gradient during the cooling process, the cooling rate within the annealing temperature range should be strictly controlled. Especially in the high temperature stage, annealing curve should be uniformly changed and the glass just removed from the furnace should not be placed on the tuyere or blown by a fan