The content of Al2O3 in clay bricks of Zhengzhou sunrise refractory company is generally above 40%, and the content of Fe2O3 is less than 2.0~2.5%. The clinker in the ingredients is 65~85%, and the combined clay is 35~15%. The pulverized bonded clay and the ground clinker are mixed and ground, and then combined with the granular clinker to prepare a semi-dry mud, which is formed by high pressure molding and fired at about 1400 ° C, and has good performance. Clay bricks for sale are weakly acidic at high temperatures, and the ability to resist alkaline slag erosion is slightly poor, but increases with increasing Al2O3 content. The thermal stability is better than that of silica bricks and magnesia bricks (see magnesia bricks).

The phosphate-impregnated product of the qualified blast furnace clay brick after drying and vacuum impregnation and secondary low-temperature sintering is used for laying the furnace lining of the blast furnace.

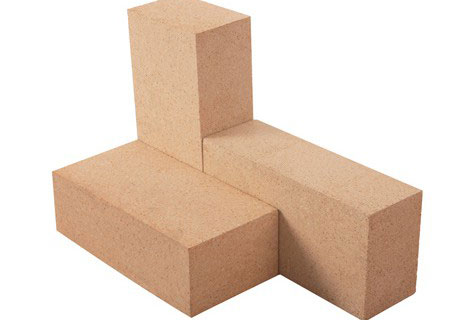

Compared with other clay bricks in the same industry, sunrise refractory products have many advantages, such as:

1. Refractoriness.

The high-aluminum brick of Tianyang refractory has higher refractoriness than clay brick and semi-silica brick, reaching 1750~1790 °C, which belongs to advanced refractory material.

2. load softening temperature.

Because high Al2O3 has high Al2O3, low impurity content and less fusible glass body, the load softening temperature is higher than that of clay brick. However, since the mullite crystal does not form a network structure, the load softening temperature still has no silicon. Brick high.

3. slag resistance.

High alumina bricks contain more Al2O3, close to neutral refractory materials, and can resist the erosion of acid slag and alkaline slag. Because of the SiO2 content, the ability to resist alkaline slag is weaker than that of acid slag.

Next, I will focus on the main uses of sunrise refractory clay bricks.

High-aluminum bricks are mainly used in masonry blast furnaces, hot blast stoves, electric furnace tops, blast furnaces, reverberatory furnaces, rotary kiln linings, cement rotary kiln transition belts, preheaters and other thermal equipment requiring thermal shock resistance; High-aluminum bricks are also widely used as open-hearth regenerative lattice bricks, plugs for sprue systems, and nozzle bricks.